Predictive maintenance solution dedicated for early detecting failures of rotating machines such as motors, pumps, fans. MOLOS.ICM is determining technical condition and predicts time to failure of monitored equipment.

Predictive maintenance solution dedicated for early detecting failures of rotating machines such as motors, pumps, fans. MOLOS.ICM is determining technical condition and predicts time to failure of monitored equipment.

Building a predictive maintenance solution requires jointly IoT technology in order to monitor working parameters and determining current technical condition of machines in combination with machine learning algorithms that predicts how this condition will look like in the future. Base on that knowledge, organization can in advance make decisions about spare parts purchase and create maintenance schedules avoiding at the same time disruptions in the production process.

MOLOS.ICM solution is dedicated for rotating machines such as motors, pumps and fans, for which it applies spectral analysis of vibrations combined with the temperature monitoring and based on those measurements, algorithms are calculating RUL (remaining Useful Lifetime) coefficient. RUL coefficient can be determined for the whole machine or for its specific components (i.e. bearing or transmission) depending on the number of sensors.

MOLOS.ICM solution is available in the regular industrial construction or in special ATEX version dedicated for the hazardous areas.

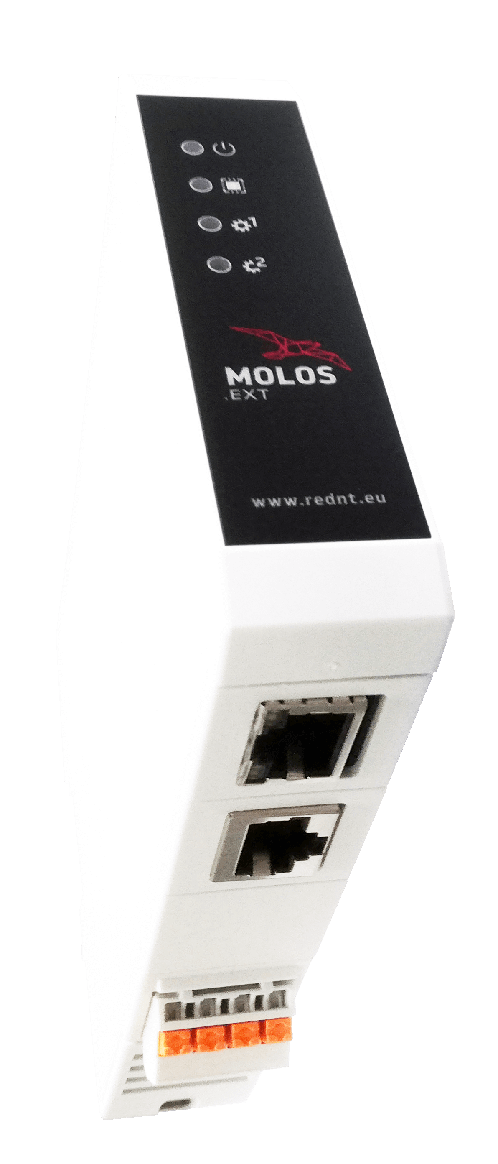

Connect non-invasive, magnetic vibration and temperature sensors to a monitored machine using industrial IoT devices MOLOS.HUB i MOLOS.EXT/FFT calculating spectral analysis on the edge and sensing results to the Microsoft Azure cloud, where machine learning algorithms are determining technical condition of the machine and calculating RUL coefficient predicting remaining time until failure.

Obtain access to the measurements and results of the ML algorithms operation using web browser, mobile application and manage push notifications with detected failures on your cell phones.

Extend the solution with the additional analog or digital measurements using MOLOS.EXT/* devices, energy consumption using MOLOS.ENERGY devices or utilize other features of the MOLOS.CLOUD framework such as data acquisition from current OT infrastructure (PLC/HMI/DCS/SCADA) or integration with the corporate tools.

Introduce digital transformation in the field of management of your critical infrastructure by introducing IoT, smart measurement systems, and machine learning technology.

Avoid unexpected costs of production downtime and optimize management of your spare parts stock

Optimize service schedules of the machines based on their real technical condition

Maintain machines in optimal working conditions and reduce up to 20% of energy costs

Reduce your service and maintenance costs up to 30% by applying remote management and predictive maintenance

MOLOS.ICM is a comprehensive predictive maintenance solution that can work as a stand-alone and autonomous system as well as can be fully integrated with the local OT infrastructure and corporate IT systems.

MOLOS.HUB for Microsoft Azure cloud communication

MOLOS.EXT/FFT for vibrations and temperatures measurements and on the edge calculations (FFT spectral determination and coefficients)

MOLOS.EXT/UI for additional analog (4-20mA and 0-10V) sensors

MOLOS.EXT/IT for additional analog (4-20mA) and temperature (PT100) sensors

MOLOS.EXT/DI for additional digital inputs

Non-invasive, magnetic vibration and temperature sensors

Special ATEX version for hazardous areas

Machine learning algorithm for determining Remaining Useful Lifetime

Online visualisation from Web application

Mobile app (iOS, Android) for incident notification

Any SCADA/Historian integration

ABB Ability™ integration

Microsoft Sharepoint integration

Microsoft Field Services integration

Microsoft Dynamics 365 integration

TLS 1.2 communication encryption support

Microsoft Active Directory for user authentication and authorization

MOLOS.ICM solution is utilized for remote monitoring and building IIoT platforms by international manufacturers of machines and by large industrial and energy companies.